End-To-End AAV Gene Therapy Solutions

Setting the Standard in AAV Gene Therapy, Together

Adeno-associated virus (AAV) gene therapies have potential to transform the way we treat certain diseases. But to deliver them successfully, robust and cost-effective production is critical.

Bring your therapy to market faster and affordably with end-to-end solutions that deliver reproducible performance and scalability with a simplified path to regulatory approvals.

AAV Gene Therapy Workflow

Spotlight on Success: Matica Biotechnology

Scaling AAV8, Together: A Collaborative Path to Process Innovation

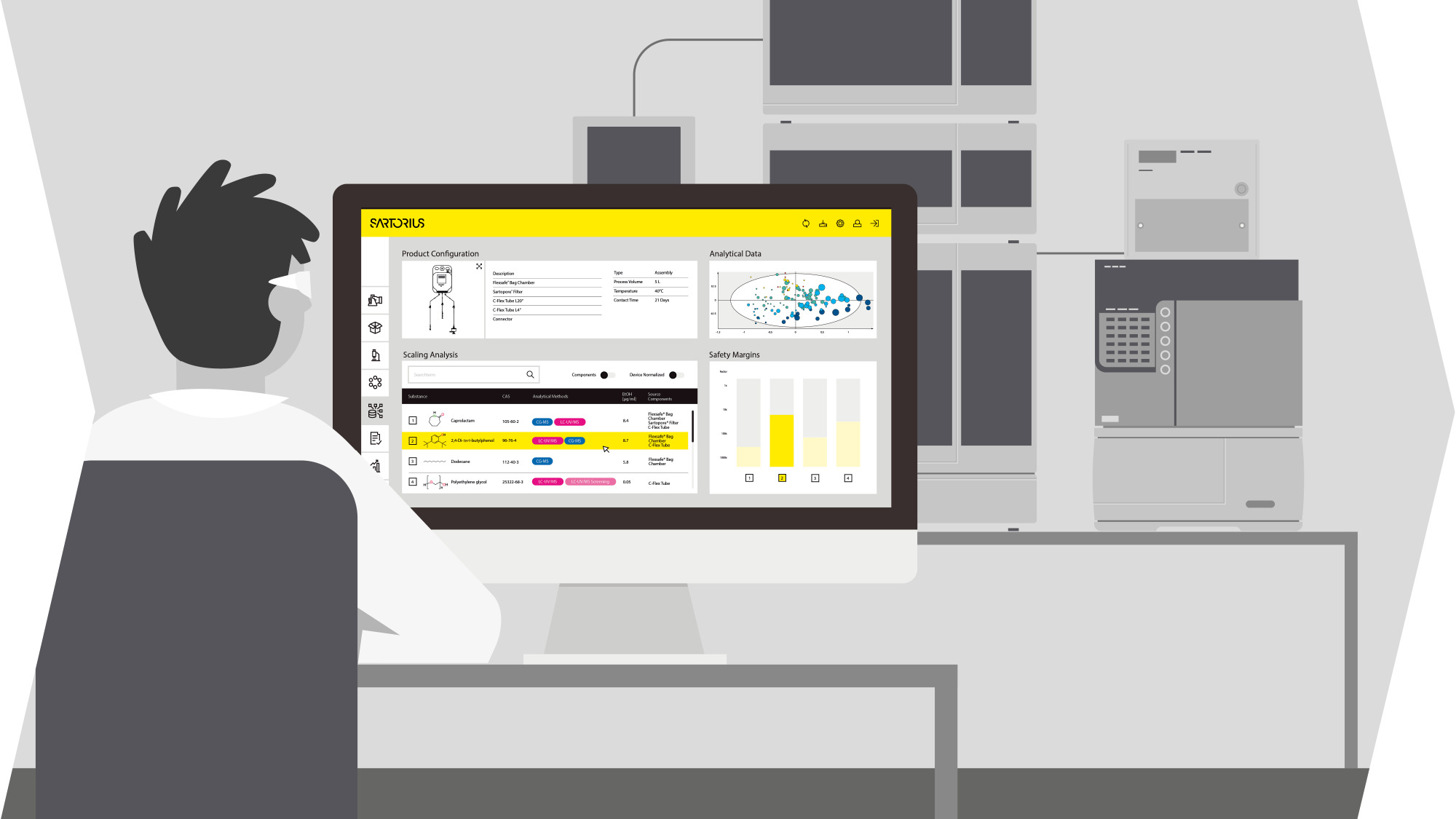

As demand for AAV therapies accelerates, developers face growing pressure to build processes that are scalable, adaptable, and compliant. To meet this challenge, Sartorius and Matica Biotechnology collaborated to create and validate a robust AAV8 production platform, demonstrating consistent performance from bench to 50 L scale. Through an integrated, data-driven approach linking upstream and downstream operations, the teams achieved reproducible titers, effective full-to-empty capsid separation, and strong impurity clearance within a flexible, GMP-aligned framework. This collaboration highlights how shared innovation can simplify complexity, accelerate scale-up, and strengthen manufacturing readiness for next-generation gene therapies.

Solutions For AAV Workflow

Request Your Sample | Raw Materials and Consumables

To help find the right materials and consumables for your needs, request a sample from our portfolio.

AAV R&D Solutions

AAV Research and Development Solutions

FAQs - AAV Gene Therapy

AAV is a small virus less than 30 nm in diameter, containing 5 kb DNA in a capsid with mostly episomal expression. It has different serotypes depending on the capsid's protein expression, supporting targeting of an organ. They are commonly produced using transfection of two to three plasmids to HEK293 — the cells then undergo purification using filtration and chromatogaphy to remove impurities.

Critical Quality Attributes (CQAs) are typically established during a risk assessment and depend on the specific drug being developed. For most drugs, the focus includes product safety, identity, sterility, purity, and potency. In the case of Adeno-Associated Virus (AAV) therapies, measuring potency is challenging. Potency assessments can involve evaluating genomic and capsid titers, as well as transduction efficiency. Ensuring purity is also crucial to avoid side effects; therefore, monitoring impurities such as empty AAV particles, DNA, and protein content is essential.

To increase performance of AAV processes, we offer HEK media and transfection reagents like FectoVIR®-AAV and pPLUS® AAV-Helper. Combined with single-use bioreactors offering the same geometry from 250 mL to 2000 L, we ensure a simplified scale-up.

We also offer solutions for clarification like Sartoclear® depth filters, Hydrosart® cassettes, Sartopore® 2 XLG sterilizing filter, and monolith columns that are scalable from process development to large-scale manufacturing — in single-use and closed formats.

Downstream processes should remove impurities like DNA and HCP to maximize drug safety and efficacy. In AAV production, separating the large amount of empty capsids — up to 80% — is challenging due to their similarity to full capsids. AAV concentration can also cause aggregation and loss due to binding to filter materials, resulting in low overall performance.

At Sartorius, we offer solutions like Sartoclear® depth filters, Hydrosart® cassettes for TFF with low-binding filters, and monolith technology with QA to efficiently remove impurities and empty capsids. Additionally, Recombumin® recombinant human albumin prevents AAV aggregation.

Related Pages

Browse additional products, services, and training for AAV gene therapy.