Filtration Systems that Maximize Production and Ensure Quality Beer and Hard Seltzer

Brewing is a complex yet fascinating process. With the rise in popularity of craft beers and hard seltzers there have been many new entrants into the market. Small- to medium-sized producers can lower costs and expand production with the right filtration equipment. We supply beverage filtration systems all round the world, offering world-class membrane filters and systems that can be adapted to a wide range of production demands. Whichever of our systems you choose you’ll be getting an easy-to-operate, low-maintenance system that produces maximum process security and is straightforward to integrate into your existing production processes.

Benefit from Sartorius’ expertise and experience and be confident in the highest quality filtration.

Beer Production Process Steps - Why use our filtration consumables?

From large scale to micro breweries, the aim is the same: a pure beverage that retains its distinctive characteristics of taste. Our product range impacts on the brewing process at several key stages:

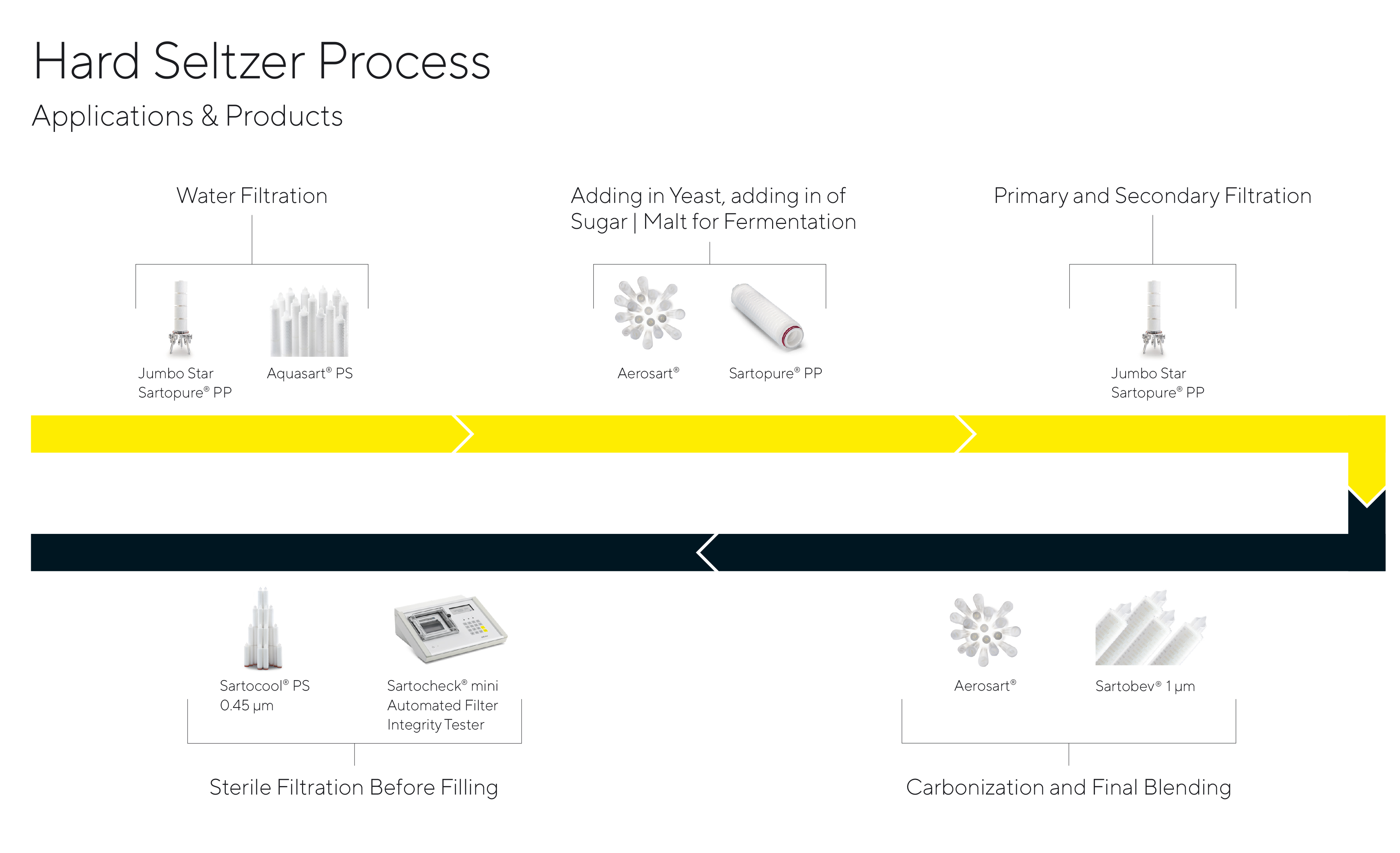

Hard Seltzer Production Process Steps - Why use our Filtration Consumables?

From low-risk new product introduction to higher volume production, selection of the right technology is important to improve the shelf life and maintain the taste profile of your hard seltzer. Our product range covers filtration products for clarification, flavor preservation, microbial stabilization and filter integrity testing.

Applications

Filtration of water in the brew house: good beer needs lots of pure water. Our Sartopure® filters improve clarification and deliver precise particle retention.

- Benefit from several polypropylene filtration layers

- Have finer, less bonded fibers and provide higher porosity

- Have unequaled filtration capacity

- Reduce particles that clog water

- Improve clarification

- Deliver more precise particle retention

- Protect the membrane cartridges and ensure the longer life of the final filters

Jumbo Star Sartopure® PP filters with pleated surfaces

Jumbo Star Sartopure® PP2 5 μm has proved an excellent filtration system for beer after the conditioning phase, maximizing production yield, whilst reducing the beer maturation process from 14 to 7 days, ensuring the same quality standard of turbidity and yeast concentration.

Aquasart® PS Membrane Filter Cartridge

Aquasart® PS 0.2 μm filter cartridges are integrity testable membrane filters especially developed for filtration of water in the Food & Beverage Industry. They are characterised by a unique hydrophilic Polyethersulfone membrane offering exceptional high flow rates and total throughputs and highest microbiological safety.

Cellar technology in the cold block. Gas filtration at this step using Sartofluor® GA filters eliminates the risk of contamination. Our Sartofluor® filters ensures:

- No risk of air contamination

- Sterile air filtration which conforms with pharmaceutical standards

- High flow rate and technical support for filter sizing

- No risk of collapsing tanks

Sartofluor® GA Cartridges for Filtration of Air & Gas

Gas filtration using Sartofluor® filters eliminates the risk of contamination. Our Sartofluor® filters ensure no risk of air contamination, sterile air filtration which conforms with standards, high flow rate and technical support for filter sizing and no risk of collapsing tanks.

Filtration using Sartopure® filters further enhances clarification. Sartopure® PP3 pre-filters are the ideal choice for particle retention, clarification and protection of final membrane in all applications. The Sartopure® PP3 series provides:

Highest robustness in pre-filtration applications based on the unique retention performance of the fleece materials.

Very low adsorption assuring the high respect of your beer aroma and taste.

Sartopure® PP Particle Reduction Filter Elements for F&B Applications

Sartopure® PP3 filter elements are high performance polypropylene fleece based pre-filters that improve your product quality. Advanced fleece materials and composition not only extend service life of your downstream membrane but also reduce filter consumption in total.

Whether using fine or trap filters we recommend Sartopure® filters at this stage. According to the filtration purpose, Aquasart®, Sartopure® PP and Sartocool® filters can be used. The latter hugely increases productivity and reduces costs. Check the filtration system through an integrity test after sterilization of the filter cartridges and before the sterile filtration of water, beer.

- Benefit from membrane filters that achieve the highest microbiological standards

- All cartridges fulfil FDA requirements

- Have excellent flow rates and protect the following filtration steps

- High flow rates reduce operation costs

- Are resistant to chemical cleaning procedures

- Have the mechanical stability withstanding the high mechanical and thermal stress

- The membranes’ low adsorption ensures that beer characteristics like foam stability are not affected

- Consistent hydrophilicity achieves constant flow rates

- Enjoy validated, testable reliability

Sartocool® PS Filters

Sartocool® PS filter cartridges enable you to achieve the highest microbiological safety for your beer. And as more and more customers prefer cold filtered beer because of its natural taste, Sartocool® is our contribution to you meeting their requirements at the same time as positively impacting on your bottom line.

Learn More about Sartocool® PS 0.45 µm

Learn More about Sartocool® PS 0.65 µm

Sartocheck® Mini Filter Integrity Tester for Food & Beverage Applications

Ensure 100% reliable filling by testing all final membrane filters with our automated testing system Sartocheck® mini.

Production of Craft Beer - Clarification by Jumbo Star Filtration System

Related Blog Posts

FAQs

Beer clarification is an important step in the brewing process as it helps in removing any solid particles, yeast, or any other impurities that may affect the taste, appearance, and shelf life of the beer. Here are some advantages of using filters for beer clarification compared to other methods:

- Improved clarity: filters can remove even the smallest particles that other methods might miss, resulting in a clearer, more visually appealing beer

- Consistency: filters can provide a consistent level of clarity across different batches of beer, which can be important for commercial brewers who need to maintain a consistent product

- Speed: filtration can be a faster process than other methods such as cold crashing or using fining agents, which can take several days to fully clarify the beer

- Shelf Life: by removing yeast and other particles, filtration can help to extend the shelf life of the beer

- Taste: some brewers believe that filtration can help to improve the taste of the beer by removing any impurities that might affect the flavor

Producing sterile beer involves several steps to ensure that the final product is free from yeast and bacteria. Here's a general process:

- Brewing: fermentation of grains with yeast to produce alcohol and carbon dioxide

- Filtration: removal of solid particles post-brewing

- Sterilization: killing remaining microorganisms using heat (flash pasteurization) or cold methods. However, heat can sometimes alter the taste of the beer, so many breweries prefer to use sterile filtration

- Sterile filtration: in sterile filtration, the beer is passed through a filter with a pore size small enough to remove any microorganisms. The Sartocool® 0.45µm cartridge, for example, uses a 0.45µm filter which is effective at removing bacteria and yeast

- Packaging: sterile packaging to prevent contamination

- Storage: controlled conditions to maintain beer quality

However, the exact process can vary depending on the specific brewery and the type of beer being produced. Contact us for a quote of Sartocool® PS 0,45µm

Download the Sartocool® PS 0.45 µm datasheet:

Sartorius offers quality control and filtration solutions for craft beer production, ensuring consistent beer quality and taste.

The filtration systems are designed to handle large volumes of beer, making them suitable for craft breweries of all sizes. These systems contribute to the beer's clarity (clarification step) and stability (final filtration step), key factors for its overall quality and shelf life.

In addition to providing technical support and training, Sartorius promotes sustainable practices to minimize environmental impact.

The Sartorius Jumbo Star System enhances beer quality by removing solids and yeast, increases production efficiency, and ensures consistent, high-quality output, crucial for maintaining brewery reputation.

- Enhances both beer quality and clarity by removing solids and yeast.

- Boosts efficiency and cost-effectiveness, designed for user-friendly operation, minimizes waste, and extends the beer's shelf life, resulting in potential cost savings.

- Versatility and Consistency, it can be used with various types of beer, ensuring a consistent, high-quality product.

- Sustainability: water and energy savings, produces minimal waste

For specific details about the Sartorius Jumbo Star System, I recommend contacting Sartorius directly