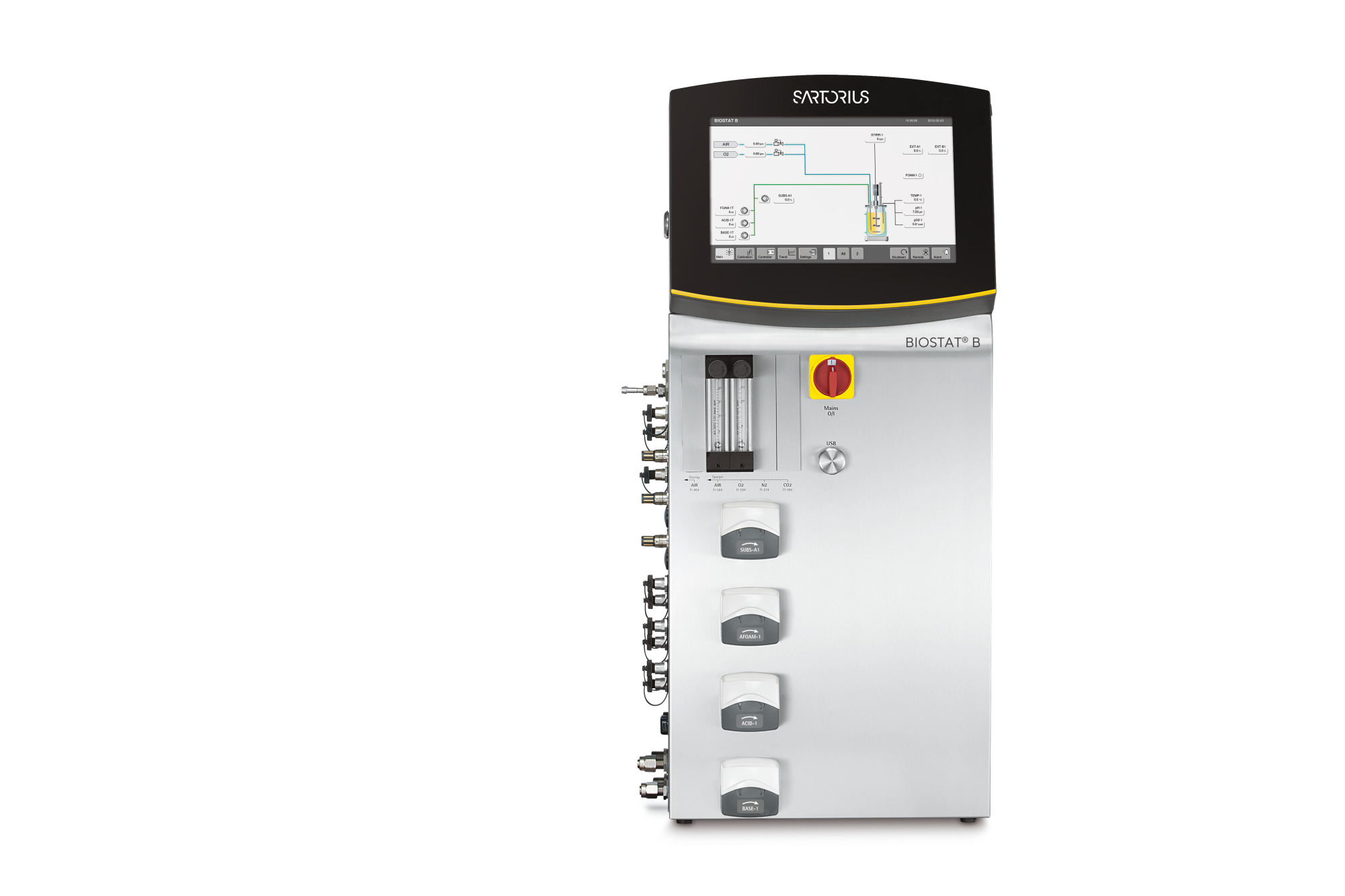

Biostat® B

The Universal Controller for Your Lab

The Biostat® B is our universal benchtop controller for stirred and rocking motion systems.

The multi-talented control tower opens up a new world of flexibility for your changing requirements. Use it as single or twin configuration, choose your cultivation chamber from our proven range of options:

- Conventional stirred-tank Univessel® Glass

- Single-use stirred-tank Univessel® SU

Biostat® B - Top Features

Designed to meet your specific needs, Biostat® B covers a wide range of applications, extending from use as a flexible basic unit for preclinical research to a fully qualified system that complies with the requirements of a validated GMP environment. You can use our Biostat® B for animal, plant and insect cell cultivation as well as for microbial fermentation.

- Stirred, reusable and single-use culture vessels - all controlled with one DCU tower

- Single or twin set-up for control of one or two culture vessel

- Gassing system comparable to our Biostat STR® with up to four mass flow controller

Configurable Design Thanks to Variety of Flexible and Scalable Options

Proven Cultivation Vessels and Advanced Automation

Our proven autoclavable borosilicate glass culture vessel is available in four different volumes: 1 L, 2 L, 5 L and 10 L for all kinds of cell culture and microbial applications.

- Classical stirred-tank design simplifies your scale-up and scale-down studies

- Extensive performance and engineering data package available

- Save additional investment and use our special design for small autoclaves

Our single-use 2 L stirred-tank vessel for cell culture applications combines scalable design with all the benefits of disposable solutions. No more worries about challenging timelines, workload or cross-contamination. Get started within minutes.

- Fully single-use vessel. DO and pH sensors

- Proven, scalable stirred-tank design

- Connection kit to upgrade existing bioreactor controllers

Design your process strategy or select different options. Configure your Biostat® B with gravimetric feed control, gravimetric level control or substrate addition profiles. This enables you to run your Biostat® B in batch, fed-batch, continuous or perfusion mode.

Besides classic DO cascade control, we have developed the unique advanced DO controller that gives you more flexibility to develop and optimize your DO control strategy.The advanced DO controller supports parallel adjustment of all DO affecting parameter settings like stirrer speed and gas flow rates of air and pure oxygen, automatically and simultaneously to control the DO set point. Optionally, you can keep the total gas flow rate constant and the ratio of pure oxygen in the gas mixture is increased automatically to match the oxygen consumption of the culture. This gives you ultimate flexibility to adapt your aeration strategy to your process requirements.

Biostat® B Applications

Biostat® B with Univessel® Glass + BioPAT® Trace

- Online measurement of glucose | lactate

- Make real-time data about glucose concentrations available to supervisory control software

Biostat® B with Univessel® Glass + BioPAT® Viamass

- Operate the BioPAT® Viamass probe without any external software

- Monitor the viable cell volume directly on the local control screen

- Make information about the viable cell volume available to supervisory control software

Learn more about BioPAT® Analyzers

Biostat® B with Univessel® Glass + BioPAT® Fundalux

- Continuous monitoring of cell growth in your culture by measuring the turbidity in a defined optical path based on near infrared light

Biostat® B with Univessel® Glass + BioPAT® Xgas

- Automatic calculation of metabolic data

- Optimization of microbial and high cell density processes