Buffer Solutions to Optimize Downstream Conditions

A consistent supply of high-quality buffers is essential for downstream processing. Tailored buffers may increase yield and efficiency. Sartorius’ global manufacturing facilities are fully comply with the highest quality and regulatory standards and provide a reliable and uninterrupted supply of powder and liquid buffers in your preferred packaging. Whether you need a standard buffer or a customized solution, Sartorius has an experienced team to guide your selection across your process.

Downstream Buffer Solutions Portfolio

Ready-to-Use Liquid Buffers

Buffers are manufactured according to precisely defined specifications:

- Sterile-grade filtration using Sartopore® 2 PES-membrane filters

- Production meets the highest quality standards

Liquids are packaged in single-use Flexsafe®️ bags ranging from 250mL to 1000L in ASTM-validated shipping containers.

- Choose from a broad range of formulations and concentrations

- Gain time and scalability

Buffer Concentrates

Improve handling & reduce footprint

Buffer Concentrated formulations are used at specific downstream steps for a broad variety of applications in the bioprocessing environment. Compared to regular buffers there are several advantages to concentrated buffers:

- Reduce labor work

- Cost-effective and time-saving

- Reducing the footprint

Sterile-Filtered WFI-Quality Water for Laboratory & Manufacturing Use

Water For Injection (WFI)-Quality Water meets or exceeds USP and EP requirements.

- Manufactured aseptically under cGMP 21CFR820 conditions by a validated sterile filtration method. Not applicable for diagnostic procedures

- Packaged in Flexsafe® Bags for use at every bioprocess step

- For media and buffer preparation, hydration, cleaning, washing, rinsing of filters or equipment

Strong Acids, Bases, Alcohols and Detergents

Sartorius offers off-the-shelf NaOH 1M in 20L Flexsafe®️ Bag for a wide variety of applications.

Strong Acids Bases, Alcohols and Detergents are critical in downstream processing:

- Used for Media & Buffer prepration, pH adjustement, Chromatography steps, Virus Clearance, Inactivation & Equipment cleaning.

- Proven chemical compatibility with Flexsafe®️ film

- Documentation for dangerous goods is available

Learn More About Buffer Solutions

Integrated Approach of Buffer Preparation

Simplify Sourcing and Logistics Thanks to a Comprehensive Offering

Buffer Solutions Across Downstream Processes

Media & Buffer Preparation

Sartorius powder media and buffers can be prepared and hydrated with WFI-quality water.

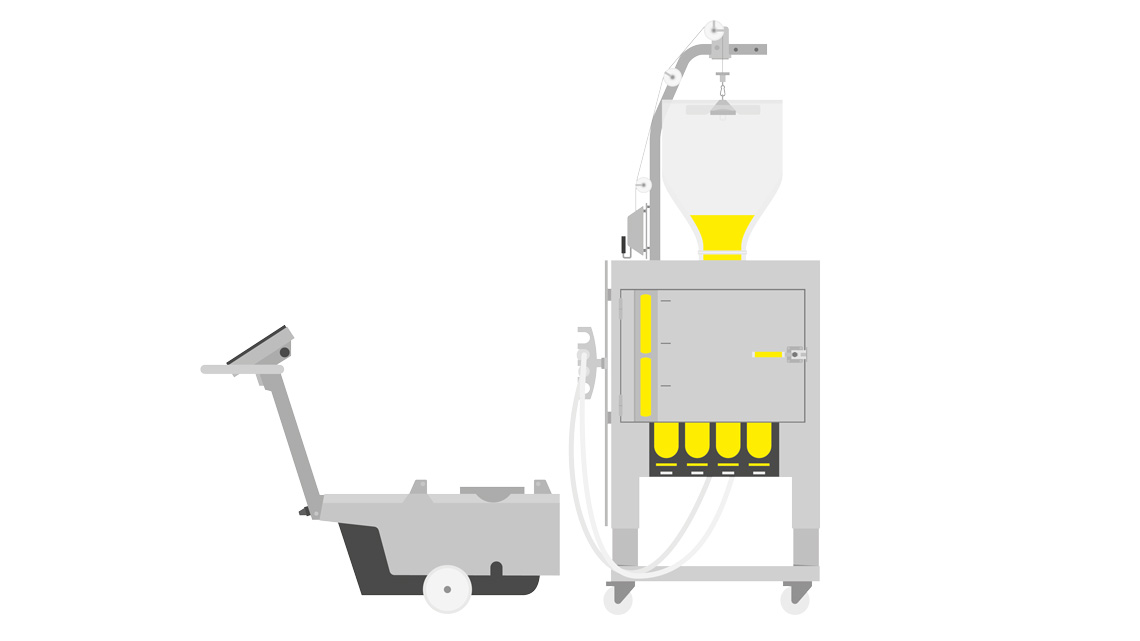

Media & Buffer Preparation with Flexsafe® Pro Mixer

The Flexsafe® Pro Mixer, pre-weighed powder buffers, and powder transfer bags ease buffer preparation for downstream processing.

Acids, Bases, Alcohols for DSP Steps

Strong acids, bases, alcohols and detergents support chromatography and purification steps in downstream process.

FAQs - Buffer Solutions

Buffer solutions can neutralize small amounts of added acid or base, maintaining the solution at a relatively stable pH. This is important for reactions and processes which require specific and stable pH ranges. For example, a change in pH disrupts hydrogen bonds, changing the shape of a protein and impacting the quality of the final product.

Water conductivity is used to measure the purity of bulk purified Water (PW) and Water for Injection (WFI) for the pharmaceutical industry. Conductivity measurements indicate the quantity of dissolved ions present in a water sample and can be used to determine water quality.

Consult Our Experts

Related Topics

Ensuring Buffer Quality

Meeting quality standards starts with approved raw materials obtained from qualified vendors.

- Super-quality materials with complete NAO (non-animal origin) traceability are used.

- Buffers, WFI-Quality Water & Dangerous Goods production systems meet both US and European Pharmacopoeia standards.

- Finished products undergo tests for sterility, osmolality, pH, and endotoxin content

Broad Capacities for Downstream Buffer Solutions

Buffer needs and volumes can become very large as processes grow and Sartorius is well-equipped to work with you on minimizing the burden associated with transport logistics by providing an extensive array of ready-to-use downstream processing buffers for protein and viral-based therapeutics.

Customized Solutions for Unique Needs

Sartorius’ production-focused buffer solutions are ideal for clients with known, desired media composition and outcome expectations. Sartorius established a global network of qualified suppliers. Customized packaging, buffers, WFI formats, dangerous goods formats, and release assays are available on request.