Implants - Quality, Safety & Efficacy for the Long Term

We’re Partners for Your Entire Development, Production Process

Medical implants – a fast-growing and highly regulated market. Whether implants are cardiovascular, neurological, orthopedic or cosmetic, the journey from development, prototype and finally to commercialization is a long one.

Within the task of maintaining a competitive edge are niche concerns such as the need for personalization, miniaturization and minimally-invasive interventions in an aging patient group. Therefore, new materials such as 100% resorbable bio-ceramics or bone substitutes made of autologous cells must guarantee long-term biocompatibility, safety and functionality.

Stringent QC is a key factor for successful commercialization of implants. It offers the potential to de-risk projects, increase success rates, significantly reduce costs, and accelerate time-to-market. Deviations or fluctuations can be detected in time to avoid higher production costs, downtimes, or product recalls.

Let Sartorius help you reach full QC potential!

Medical Device Manufacturing Featured Products

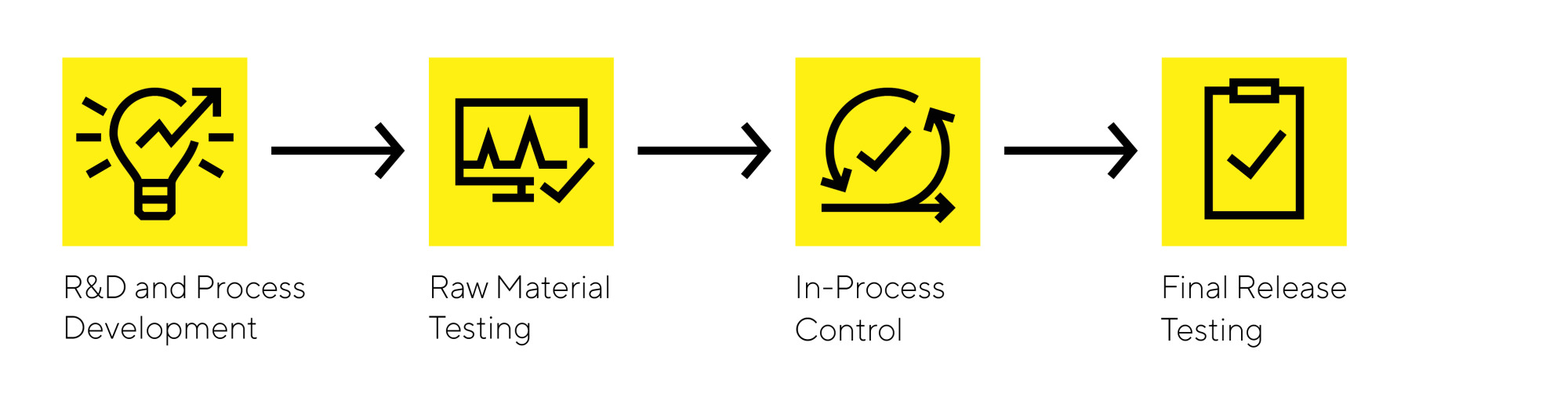

Medical Device Manufacturing Workflow

R&D and Process Development

New materials with better biocompatibility and resistance to mechanical stresses enable personalized, miniaturized, and more customizable devices. It all starts in the design and development phase.

Discover R&D and Process Development solutions for your application:

- Density Check of Solid Material & Liquids

- Nanoparticle Concentration

- Chemical Characterization - Biocompatibility

- Cytotoxicity - Biocompatibility

- Data Analytics

Raw Material Testing

The quality of the final product depends on the quality of the raw materials. To ensure device performance and patient safety, your raw materials must be stable and safe for use and meet stringent ISO, USP, EP, ChP, JP, and ARTG testing standards.

Discover the Raw Material Testing solutions for your application:

- Density Check of Solid Material & Liquids

- Moisture Determination of Raw Material

- Particulate Matter Analysis

- Chemical Characterization - Biocompatibility

- Microbial Testing: Water & Bioburden Testing

In-Process Control

In-process quality control tests are performed at regular intervals to verify product quality and specifications at every stage of production.

Test calcium phosphate materials for moisture content or particulate matter of polymer-based tissues. Check sterility of cochlear implants or perform a weighing step to validate the coating of an interposition implant.

Discover the In-Process Control solution for your application:

- Check Coatings – Application of Correct Amounts

- Moisture Determination

- Nanoparticle Filtration of Liquids - Concentration – Detection

- Particulate Matter Analysis

- Continuous Microbial Air Monitoring

- Rinsing & Sterile Preparation

- Data Analytics

- Counting with Reference Weight

Final Release Testing

Every prosthesis, surgical mesh, scaffold, or breast implant must meet safety, efficacy, and quality standards, such as ISO 11607. Testing prevents device defects and ensures that the finished products are stable and safe for long-term use.

Discover the Final Release Testing solutions for your application:

- Check Coatings Application

- Error-Proof Packaging

- Density Check of Solid Material & Liquids

- Moisture Determination of Packaging Material

- Microbial Testing: Bioburden & Sterility

- Chemical Characterization - Biocompatibility

Featured Products

Cubis® II Microbalance

Weighing by difference solutions are your best fit to verify coating systems have applied the exact amount of medical grade polymer or API.

Arium® Comfort II Ultrapure Water System

Sartorius Water Purification Systems provide ultrapure water for impurity-free and safe operation

Microsart® @filter

Membrane filtration solutions for standard microbial enumeration protocols facilitate accurate detection of potentially pathogenic or spoilage microorganisms.

Frequently Asked Questions

Thanks to an intuitive application, the balance determines the density of solids using the buoyancy method. The sample is first weighed in air, then submerged in liquid. Based on the two weight values the application calculates the sample density.

Density of solid: Rho = abs ((weight in air * RhoFl)/(weight in air - weight in liquid))

Design of Experiments (DOE) is a data analytics method that helps you plan, conduct, analyze and interpret controlled tests to determine which factors exert influence over your product quality, stability or other key process attributes. Rather than experimenting with one parameter at a time, DOE speeds up the process and helps you identify important interactions by manipulating multiple factors at the same time.

Get rid of drifting weight values caused by electrostatic effects with the built-in ionizing technology of the Cubis® II analytical balance. The ionizer can be started with the simple press of a button or automatically when the draft shield door closes. Cubis® II draft shield glass panels are coated with conductive layers, preventing external transfer of electrostatic charges generated by the environment, ensuring reliable and stable weighing results.

Download the infographic: Charge Neutralizing Technology Ensures Accurate Weighing