Octet® BLI Automation and Integration

From discovery through process development to manufacturing, Octet® Biolayer Interferometry (BLI) systems are automation-ready and robot-compatible, integrating seamlessly into a wide array of biologic workflows. As the demand for automation of real-time label-free assays continues to rise, many traditional techniques prove challenging to automate. Our portfolio of proven solutions streamlines the automation process, helping you achieve faster time-to-market and cost savings.

From IgG titer to epitope binning, our BLI platform combines label-free molecular interaction analysis with cutting-edge high-throughput systems. These systems facilitate the rapid characterization and development of biologics drug molecules. Featuring high detection sensitivity, and throughput, along with compatibility with 384-well microplates, Octet® BLI systems will enhance discovery and development with reproducible performance and scalability, offering a simplified pathway to success.

Systems

Octet® RH96

96-Channel Ultra High-Throughput Octet® System

Monitors up to 96 biosensors simultaneously, enabling label-free detection for protein quantitation and kinetic characterization at unmatched speed.

- 96-well quantitation in as little as two minutes

- Simultaneously reads 8, 16, 32, 48, or 96 wells

- Supports 96-well and 384-well microplate format

- Two microplate locations to maximize throughput and improve workflow

Octet® RH16

16-Channel High-Throughput Octet® System

Ideal for high-throughput applications that demand high sensitivity and low sample volume requirements.

- Analyze up to 16 samples simultaneously

- Supports 96-well and 384-well microplate format

- Two microplate locations to maximize throughput and improve workflow

Features and Benefits

Octet® BLI automation will improve sample throughput, reduce operator time, and streamline data audit trails.

- Software API available for external function calls

- Compatible with ANSI/SLAS standard labware

- Chamfered loading nests

- Spacing for robotic fingers to grip the sides of the plate

- Small footprint

- Very robust

- GxP packages with 21 CFR Part 11 software

- Increase throughput

- Increase walkaway time

- Reduce human errors

- Offer environmental control

- Improve space utilization

- Improve worker safety

- Easy to use

Example Solutions

Small Workcell

Begin automating a portion of your workflow by integrating the Octet® system with Biosero.

- Samples are queued on static storage hotels and wait to be loaded onto the Octet® RH96

- A robotic arm with an integrated barcode reader automates sample loading

- Green Button Go easily allows users to select which sample plates run automatically

Optional: Add an external incubator for additional environmental storage

Medium Workcell

Increase throughput with parallel processes and additional automated steps.

- Double your throughput with two Octet® RH96 systems

- Centrifugate plates and seal for medium-term ambient storage

- Use larger ambient plate storage to hold sample plates and biosensor trays

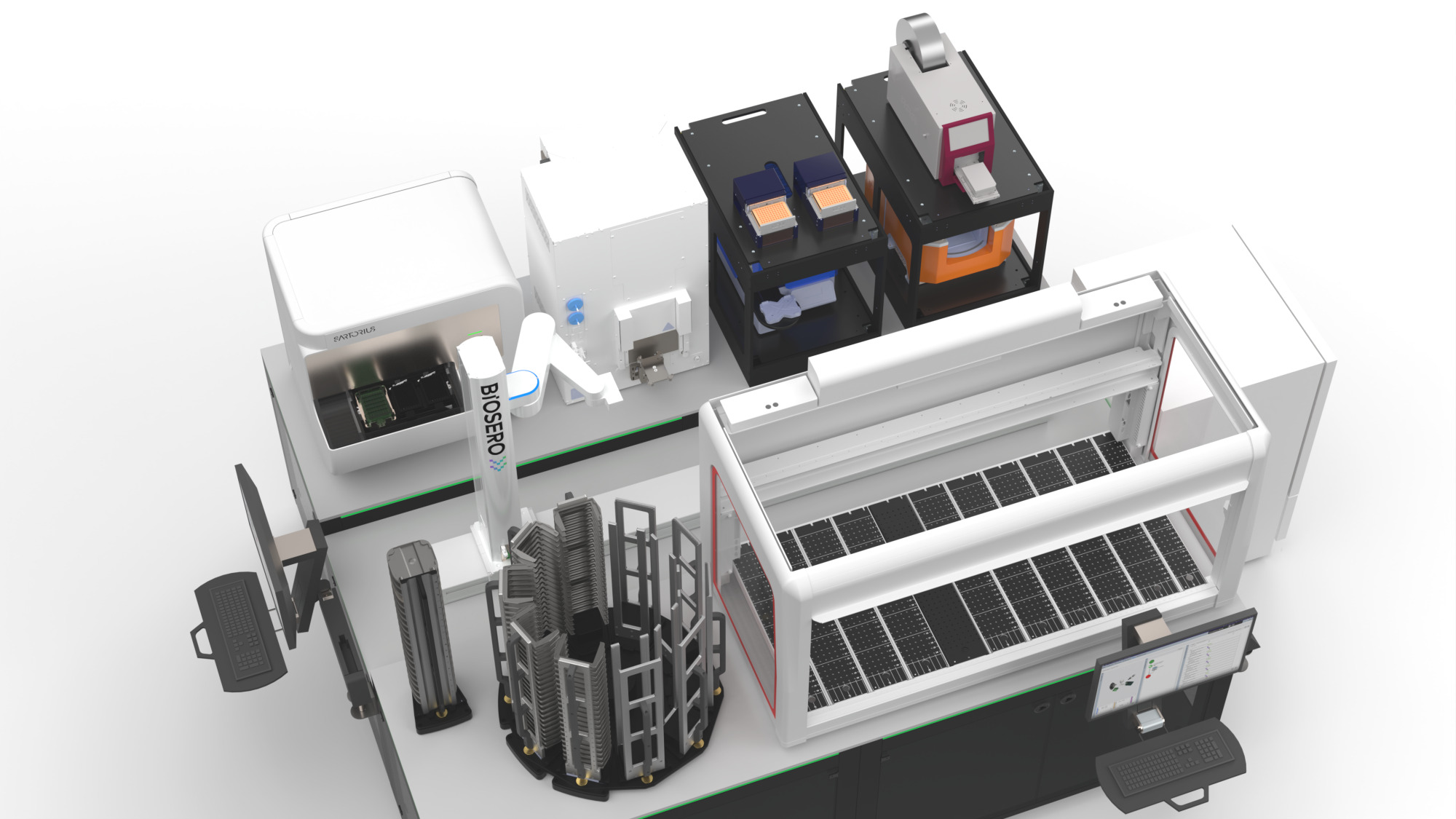

Large Workcell

Build end-to-end automated workflows to custom specifications to achieve unique research goals.

- Automate various plate preparation protocols and free up valuable space on the liquid handling deck to get more use out of your liquid handler (LH)

Featured Applications

Cell Line Development

Biology waits for no one. If cells need refeeding at 3 a.m. or imaging over the weekend, scientists must go to the lab and tend to them. With automation, however, the workcell can automatically schedule runs and record data, even making data-driven decisions as the cells grow.

This example cell line development system uses a liquid handler for refeeding, transfection, and all other liquid handling needs. An automated Incubator stores all reagents and cell plates, while an automated screw capper caps and recaps tube racks. Finally, the imaging cytometer is utilized for sample confluence reads.

In this example, single cells are plated from a single cell dispenser, they are re-fed and grown, imaged at defined time points, and then transfected once a certain confluency level is reached. This solution enables scientists to automate longer portions of their workflow minimizing manual touchpoints that slow down the work or require extreme working hours.

Partners

Octet® BLI Automation Powered by Green Button Go

Biosero® is the preferred automation partner for the Octet® BLI platform, accelerating real-time, label-free assays to support bioprocess and drug discovery workflows. Octet® systems seamlessly integrate with Biosero’s Green Button Go® software to participate into end-to-end automated workflows with multiple devices from different manufacturers.

Biosero® designs and builds integrated laboratory automation solutions through Green Button Go for top labs around the world.

Once deployed in Green Button Go®, Octet® systems can be scheduled to run alongside other required automation tools to deliver results at any time of day.

Green Button Go’s operator friendliness, flexibility, and best-in-class error handling help to keep automation solutions running longer with less downtime.

Automated workcell images provided by Biosero.