Dynamic Perfusion Delivers Highest Productivity in Smallest Footprint

Upstream Intensification for Challenging Modalities and Molecules

Established manufacturers are looking to single-use, flexible solutions when building new facilities or modifying existing operations. Their goal is to increase productivity across different modalities including difficult-to-express molecules. Meanwhile, early-stage drug development companies are looking for low upfront investment for their lower throughput products. With smaller bioreactor requirements that deliver higher productivity per batch, dynamic perfusion can be the answer in both cases.

DPでは体積生産性が最大5倍高いため、モジュラーアプローチを考慮に入れることができ、より小型のバイオリアクター(2000リットル未満)で迅速な立ち上げ時間が実現できます。

DP法では、1日あたり2~5 g/Lの生産が実現可能で、2週間以上にわたり製品の連続ハーベストが行えます。これにより、フェドバッチ法と比較して最大5倍の生産性向上が達成されます。

継続的なハーベストにより、製品の安定性と品質が最適に保たれます。これは分解しやすい不安定な分子にとって極めて重要です。

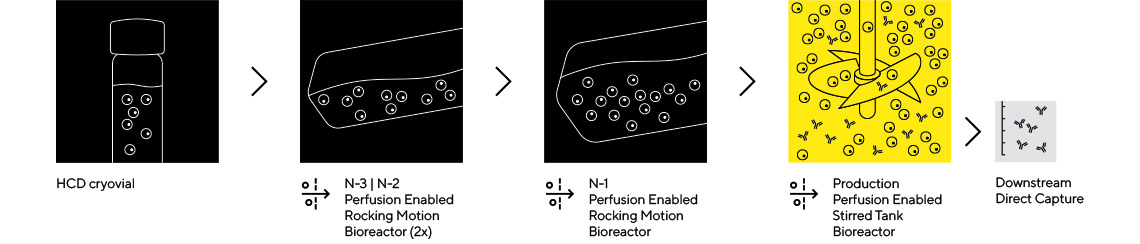

Intensified Seed Train and Production Options

動的パーフュージョンは、少ないことがより大きな効果をもたらすことを証明しています

500リットルバイオリアクターにおいて最大5倍の生産性向上を実現

動的パーフュージョン培養では、精密ろ過により製品を継続的にハーベストすることが可能です。この手法は小型バイオリアクターで実現できるため、設置面積を削減し、初期設備投資を最大60%低減できます。標準的なフェドバッチ法と比較して生産性を最大5倍向上させると同時に、発現が困難な分子を含む複数の分子パイプラインに対して柔軟性を有してサポートします。

A Cost Effective Upstream Intensification Option

Implementing rocking motion bioreactor, with integrated perfusion membrane, in the N-1 seed train step is the most cost-effective opportunity for seed train intensification for high inoculum fed-batch process. Using the RM bioreactor manufacturers can

- Reduce both capital and consumable investment by >30%

- Achieve high cell densities at lower volumes to inoculate production bioreactor

- Increase productivity and overall facility throughput by 30-50% thus decreasing overall COGS by up to 50%

Increased Flexibility by Implementing Dynamic Perfusion

Running a bioreactor in dynamic perfusion (DP) mode enables the use of smaller bioreactors, such as the Biostat STR® 500 L with integrated XCell ATF® technology, to run perfusion in microfiltration mode. Dynamic perfusion usually does not use cell bleeds, which results in increased viable cell density (VCD) as the product is harvested continuously for the next 15-20 days. This operation can lead to:

- Increased productivity up to 5 times

- Increased flexibility for executing multi-modality facility

- Additional benefits for difficult-to-express molecules (bispecifics and multispecifics)

培地管理

Ensuring Media Quality and Stability Is Critical for Intensification

Consistent cell culture performance in intensified processes is dependent on the media design, quality, and stability. In dynamic perfusion, fresh medium and feeds are added continuously over 15-20 production days, thus requiring smart media strategies. Consumables and equipment to handle these volumes are essential to support a smooth process flow, while reliable filters to avoid contamination and remove mycoplasma are critical for successful intensified processes.

The Flexsafe® Pro Mixer Saves Time Without Compromising Control

Flexsafe® Pro Mixer is an efficient, single-use mixer for 50 L up to 3000 L. It provides the high levels of control that are essential for cGMP biomanufacturing.

- Saves time with fast powder dissolution

- Preserves quality of shear sensitive fluids through low shear mixing and high torque

- Designed for rapid set-up and efficient changeover (in less than 10 minutes) reducing risk of damage and loss from product mishandling

- Includes full material characterization and safety evaluation

Single-Use Bags

2D Single-Use Bags

Storage to Support the Media Volume Required for Dynamic Perfusion

Sartorius Flexsafe® 2D Single-Use Bags ensure the stability and integrity of the medium, allowing excellent, reproducible cell growth. The superior strength of the polyethylene film reduces risk of damage, while its flexibility enables consistent performance and easy handling.

3D Single-Use Bags

Self-Deploying and Filling 3D Single-Use Bags for Pallet Tanks

Liquid medium must be prepared and safely stored to be ready whenever it is needed – and in the case of dynamic perfusion, larger scale liquid storage is often required. Flexsafe® 3D Single-Use Bags, designed for storage applications in pallet tanks, are easy to use and allow excellent and reproducible cell growth. With a self-deploying accessory, the bag can be filled with no operator manipulation. These ready-to-use bags have “plug and play” compatibility with Sartorius Biostat STR® bioreactors.

Ensuring Quality and Safety of Cell Culture Medium

Companies are looking more and more for virus removal filters for media for risk mitigation purposes. Virosart® Media filters, provide high virus clearance safety and show superior capacities for media used for mAbs and recombinant proteins.

Cost Efficient Media Filtration with High Mycoplasma Retention

Sartopore® 2 XLM sterile filters are used for cost-efficient media filtration with outstanding high throughput. They feature a 30% larger surface area and optimized pre-filter layers which results in a higher flow rate and higher throughput. The Sartopore® 2 XLM is an advanced 0.1 µm rated filter with high mycoplasma retention.

Process Data Analytics

Assurance Through Multivariate Data Analytics

Customers rely on enhanced data analytics for process intensification due to the complexity of operations, processes and data as well as the total cost of risk. Multivariate Data Analysis (MVDA) extracts meaningful information from large data sets, enabling scale-up and batch-to-batch comparison investigations to improve the quality, safety, and efficacy of a drug product.

SIMCA®はプロセスの健全性と製造の成功を保証します

SIMCA®は、大量のデータからアクション可能な情報を得て、一貫したプロセスと製品品質を確保するための進化したデータ分析ソリューションです。SIMCA®は、投入される原材料を分析し、それらが細胞増殖、生存率、生産性、品質にどのように影響するかを判断します。これは動的パーフュージョンにおいて極めて重要です。この堅牢な多変量解析エンジンは、バッチ間の品質を比較し、あらゆる変動の原因を特定します。直感的なインターフェイスと分かりやすいインタラクティブな可視化を通じてアクセシブルです。

SIMCA®-onlineは、リアルタイムモニターと制御を統合します

多変量リアルタイムモニターは、特に強化されたプロセスにおいて重要です。SIMCA®がプロセスの基準となるデジタル指紋を作成する一方、SIMCA®-onlineはリアルタイム測定値を用いてこの指紋に基づきオペレーションを評価します。つまり、現在のバッチ指紋が基準と一致しているかどうかを検証するのです。基準からの逸脱が確認された場合、プロセスを即座に馴化することが可能です。この自動化された是正アクションにより、品質の一貫性が保たれ、効率が最大化され、コスト削減が実現します。