Ambr® 15 - Advanced Microbioreactor System

For Cell Line Selection and Early Process Development

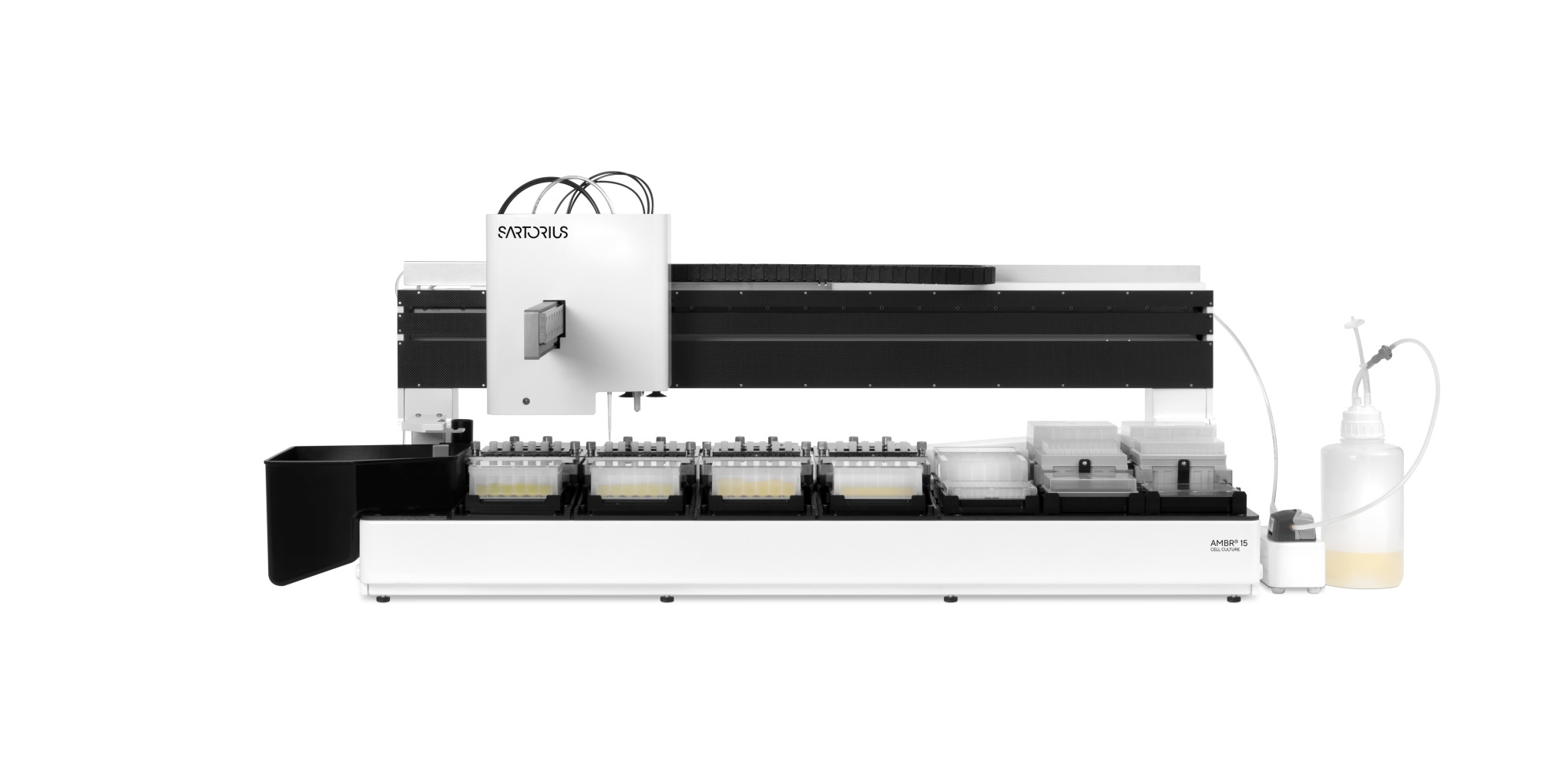

Ambr® 15 Cell Culture is a high throughput, automated bioreactor system for 24 or 48 parallel cultivations at the 10 –15 mL microbioreactor scale. This platform enables selection of the best clones, media and feeds under small-scale bioreactor conditions, ensuring a seamless scale-up. Implemented in Cell Line Development (CLD) laboratories worldwide, Ambr® 15 Cell Culture makes experimentation more cost effective by saving on labor, facility space, capital, media and consumables.

Leave shake flasks and shaking plates behind to increase cell productivity and ensure robust performance.

With up to 48 bioreactors running in parallel one operator can screen more clones and conduct multi-factor DOE studies.

Single-use bioreactors save setup time, reducing staff costs and turnaround time.

Liquid handling automation reduces variation and risk of human error.

A one-year license for Ambr® Clone Selection software is included, simplifying ranking analysis.

Parallel Operation of up to 48 Microbioreactors

The Ambr® 15 Cell Culture system includes single-use vessels, an automated workstation and powerful software. Installed in a biosafety cabinet for aseptic operation, Ambr® 15 monitors and controls 24 or 48 microbioreactor cultures in parallel to provide a reliable microscale model for upstream processes. Implemented in CLD workflows of major pharma and biologics companies as well as research and academic institutes.

Ambr® 15 Cell Culture Generation 2

Ambr® 15 Generation 2 Design

With an improved design, this next generation system offers better performance, increased process flexibility and expanded capabilities to support a wide range of upstream applications.

Automated Workstation

Automation of Parallel Experiments Offers Unparalleled Control

Fully automated parallel processing, monitoring and control with:

- New features: improved liquid handling, new culture station design, flexible deck layout and rapid vessel drain

- Standard and cooled workstation configurations

- Individual set point, monitoring and closed-loop control of pH and DO

- Independent control of O2, CO2 and N2 for each microbioreactor

- User-defined temperature and stirring set points for each culture station

- Extended low speed stirring range down to 150 rpm

Culture Stations

Flexibilty Within and Across Culture Stations

The culture stations are located on the workstation deck: two culture stations in a 24-way system, four in a 48-way system – each station holds 12 microbioreactors.

Temperature and stirring speed are consistent within a single culture station but can vary between different culture stations.

pH, DO, gassing, liquids feeds and samples are controlled independently for each individual bioreactor within a culture station.

Microbioreactors

A Microscale Preview of Lab-Scale Potential

Ambr® 15 microbioreactor vessels mimic the characteristics of lab scale bioreactors to enable optimal cell growth, productivity and product quality.

- 10 – 15 mL working volumes

- Single-use pH and DO sensors

- Integrated pitched blade impeller

- Port for liquid additions and for sampling

- Vessels with sparge tube for gassing into the impeller mixing zone, or without for headspace gassing

- Vessels available with temperature compensation for lower temperature applications

Control Software

The Power to Plan and Execute Ambr® 15 Experiments

Ambr® 15 control software supports:

- Easy experiment construction

- Effective process monitoring and control

- Detailed recording and data analysis with audit trail

- New software steps for media mixing, passaging and rapid vessel drain operations

The Ambr® 15 software includes a license for MODDE® DOE to assist with experiment planning and execution.

Process parameters and other variables can be tagged in Ambr® 15 to facilitate DOE, enabling easy transfer and analysis of results in MODDE®.

Modes of Operation

Ambr® 15 Cell Culture Modalities

Ambr® 15 Cell Culture is a microscale bioreactor model that reduces bottlenecks and accelerates development across a range of upstream applications. With the ability to efficiently explore different modes of operation, it is easy to investigate how cell lines and clones behave under batch, fed-batch and perfusion-mimic conditions, while the capability of media exchanges supports development of processes for cell and gene-based therapies.

Clone Selection

Highly Productive Clones With Optimal Quality Starts With Selection

Assessing clone performance in small-scale bioreactors ensures results translate at scale. Ambr® 15 Cell Culture combined with Ambr® Clone Selection for clone ranking optimizes workflows to reduce cell line development timelines and increase productivity.

Media and Feed Optimization

Streamline and Simplify Media and Feed Evaluation

Optimization of media and feeds can improve cell growth and productivity. Ambr® 15 Cell Culture control software enables the creation of media blends in plates on the deck or directly in the microbioreactors. Automated liquid handling saves time and reduces risk of error.

Early Process Parameter Definition

High Throughput Experimentation Alleviates Major Development Bottlenecks

Protocols can rapidly be established for both stable and transient cell lines. Parallel operation allows testing of multiple factors to define process parameters early in development, while Design of Experiments (DOE) embedded in the Ambr® 15 software facilitates the multifactorial experimental design and analysis.

Perfusion Mimic

Screening Under Perfusion Mimic Conditions

Ambr® 15 Cell Culture’s Rapid Vessel Drain option removes supernatant from settled cultures directly from the microbioreactors quickly and efficiently. The Ambr® 15 software includes novel process steps, such as cell bleeding based on cell count data, to automate perfusion mimic protocols.

Analyzer Options

Ambr® Analysis Module

Integration of the Analysis module with Ambr® 15 for at-line pH measurements automates bioreactor sensor calibration and in-process pH checks, while the Analysis module with BioPAT® Spectro allows connection to selected 3rd party Raman Spectrometers for spectroscopic analysis of bioreactor samples.

Integrated Cell Counters

The Ambr® 15 Cell Culture system can connect directly to the Beckman Vi-CELL™ XR or Roche Cedex HiRes for cell count measurements, or to the Nova Biomedical BioProfile® FLEX2 for cell counts and metabolite analysis. Samples transfer through a sample line to the integrated analyzers, and measurement results transfer back to the Ambr® 15 software for monitoring and process control.

Data-Connected Analyzers

The Octet® Label-free Detection Systems and Waters™ BioAccord™ LC-MS can connect to Ambr® 15 to transfer bioreactor sample data to the analyzer and return results to the Ambr® 15 software. Samples are manually transported between the systems.

Details

An Interactive Overview of the Ambr® 15 Cell Culture Workstation

Click the signs to learn more about the features that make the Ambr® 15 Cell Culture the bioreactor system of choice for Cell Line Development laboratories worldwide. This technology enables the selection of the best clones, media and feeds under small-scale bioreactor conditions for a seamless scale-up, all while saving on labor, facility space, capital expenditures, media and consumables.

Product Demo

Ambr® 15 Cell Culture Workstation

Ambr® 15 Cell Culture Microbioreactor

Learn More About Ambr® 15 Cell Culture

Ambr® 15 Downloads

Explore brochures, posters and application notes on Ambr® 15 for a full understanding of how the lab-scale bioreactor can increase productivity while reducing timelines across a number of applications.