Medical Device Quality Control: Ensure Reliable Manufacturing

The Journey from Medical Device Development Commercialization is a Long One. We’re Partners for Your Entire Process.

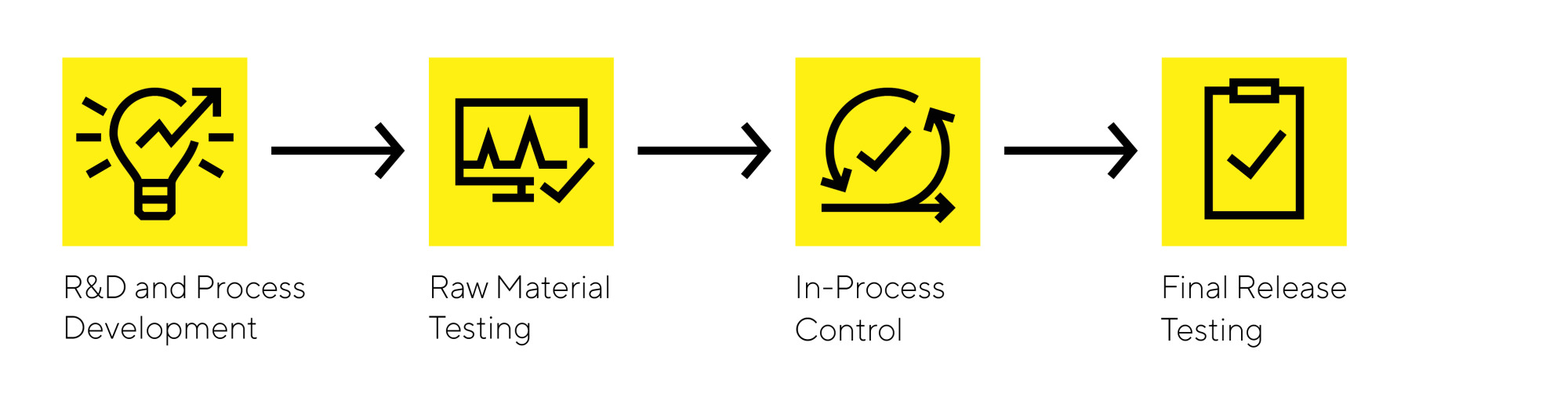

To stay competitive in the medical device market, companies should focus on niche areas like personalized and miniaturized devices for aging patients. New technologies, such as 100% resorbable bio-ceramics and autologous cell-based bone substitutes, must ensure long-term biocompatibility, safety, and functionality. In-process quality control tests are crucial to verify product quality and specifications at every stage of production.

Sartorius offers smart and robust solutions for medical device quality control, including testing for correct dose delivery, moisture content, sterility, and ultrapure dialysis fluid.

Access the Medical Devices Guide Join the Medical Devices Newsletter

Explore the Medical Device Production Process

Partners for Your Entire Process

Discover Solutions for Your Workflow

Product Highlights

Weighing Solutions for Medical Devices Applications

Precision Analytical Balances for Drug Delivery Systems for Accurate, Reliable Results and Increased Productivity

The Cubis® II analytical balance is designed for high-performance weighing and offers digital workflow management following US FDA data integrity principles (ALCOA). On-board QApps contribute to correct usage by guiding users through weighing processes, increasing measurement accuracy, precision and process safety.

The Pharma Software Application Package supports compliance with FDA 21 CFR Part 11 and EU GMP Annex 11, USP Chapter 41 and includes features like user management, digital signatures, audit trail and minimum sample weight determination.

Active Air Monitoring and Sampling for Clean Room Environments

Efficient, Reliable, User-Friendly Microbiological Testing Solutions for Medical Devices

Choose total safety and convenience using Sartorius MD8 Airscan® technology. Collect samples using a single gelatin membrane filter, without interfering with zone protection.

Proprietary, USP-approved filters retain the smallest airborne microorganisms, practically ruling out false-negative results. Conveniently focus on other tasks, while your air sampler eliminates the need for manipulation or changing agar plates.

Simplify Lab Water Use

To maximize lab space capabilities, your water system should adapt to your needs. Users need full control over quality parameters at the point of use and the ability to fill containers of different size at the same time.

The innovative, flexible Arium® Smart Station addresses these requirements. Dispense water in the exact quality and quantities required for your experiments, when and where you need it.

Why Choose Sartorius for Quality Testing?

State-of-the-art lab instrumentation with built-in applications and security settings:

- Simplify operation

- Increase measurement precision

- Support safe and stable testing processes

- Reduce probability of human error

Sartorius products are developed, produced, and distributed to ISO 9001 Quality Management System standards. They meet stringent quality control standards throughout all manufacturing steps and are backed by quality assurance certificates that guarantee conformity to specifications.

Lab balances connect seamlessly to user management systems generating traceable results. Software solutions support your documentation compliant to US FDA 21 CFR Part 11, EU GMP Annex 11 or ALCOA.

Optimize your process, identify important correlations or diagnose root causes of problems to significantly reduce experimental costs, de-risk projects and increase success rates. Achieve your quality goals and Quality by Design (QbD) requirements.

Applications

Medical Device Quality Control Solutions

Our solutions enable precise and accurate testing, ensuring long-term biocompatibility, safety, and functionality of medical devices. With Sartorius, you can enhance your quality control processes and ensure compliance with industry standards. Find solutions for many applications below.

Sartorius provides advanced pump testing solutions tailored for the medical device industry, ensuring the precision and reliability of pumps used in critical applications.

Cubis® II balances, including the MCA66S micro balance and MCA225S semi-micro balance, are designed to meet rigorous industry standards such as AAMI TIR 101, IEC 60601-2-24, FDA, MDR, and GMP.

Key features and benefits include:

- Ultra-high resolution balances for exceptional precision in flow rate and accuracy testing

- Precision and compliance with industry standards for infusion pump testing

- Comprehensive service support, including accredited calibration in accordance with ISO |IEC 17025

Lab balances are indispensable instruments in the medical device industry. They are used at several stages of quality control to count large numbers of components based on individual weight, verify no part is missing, control deviations of purity in raw materials or optimize ceramic, plastic or pharmaceutical coatings.

Sartorius balances provide the weighing capacities needed by ensuring full traceability of data, time-saving workflows and accurate results.

- Highest precision for smallest quantities

- Protected against drafts and electrostatic charges

- Check density of solids, liquids, and pastes with one balance, even with densities in excess of 3 g/cm3

- Sample holders accommodate products of various shapes

- Full data traceability and integrity, connect to your ERP

- Compliant to 21 CFR part 11 and EU Annex 11

Request More Information Explore Backweighing Solutions

Compendium: Weighing Application Compendium Density Determination

Raw and packaging materials can vary in characteristics and hygroscopic properties. However, they need a specific moisture or solid content for optimal processing and to assure appearance and functionality of the final product. Current standards, such as the ASTMD1417-16 for determination of total solid content of latex, are critical for further processing of wearables, devices and personal protective equipment (PPE).

Sartorius offers robust and reliable MA160 Moisture Analyzers to detect and document moisture content quickly and easily within routine applications.

- Achieve the highest precision, even for very dry samples

- High memory capacity to store up to 100 methods and efficiently manage them in a library

- Ensure rapid heating and fast uniform drying of samples with up to 30% quicker analysis

Application Note: Fast and Precise Determination of Total Solid Content of Latex

ISO 10993-1 requests a safety evaluation and risk assessment to exclude potential harmful effects of constituent materials, as for nanomaterials. Prior to evaluating reference values, like conjugation or encapsulation efficiency, zeta potential and size distribution, successful purification and concentration of suspension or dispersion is essential. However, typical separation methods like size-exclusion chromatography and dialysis require subsequent concentration steps and extensive manual handling that is time-consuming and costly.

Sartorius Vivaspin® Lab Ultrafiltration devices move you one step ahead:

- Perform purification and concentration steps simultaneously, reducing manual handling time

- Highest recovery in the fastest possible time

- Save consumable costs

Application Note: An Improved Method to Wash Graphene Prior to Use as a Drug Delivery Vehicle

Biological response to medical devices depends on constitutive components and classification.

The biological risk of a system is often directly linked to its surface properties and material constituents. Assessing the composition of materials and their ability to release leachables and extractables (L&E) is standard in evaluating biocompatibility. FTIR, MS, ICP-MS or GC require robust, reliable sample preparation and streamlined workflows to ensure clean, reproducible, interference-free results.

Sartorius provides user-friendly sample prep tools for chemical characterization per ISO 10993-18. Time-saving solutions for preparing samples for content and purity analysis produces robust and reliable sample processing procedures.

- Arium® Mini Plus UV with Unique Bag Technology produce ASTM Type 1 ultrapure water to minimize chemical ion interference, ensure consistent baselines and avoid background noise

- Cubis® II lab balances with 21 CFR Part 11 & EU GMP Annex 11, USP Chapter 41-compliant records

- Minisart® filtration devices with minimal leachables, extractables and interferences

Cytotoxicity testing is a standard biocompatibility test to evaluate toxicity levels or irritancy potential of the device or material. According to ISO 10993-5, the quantitative MTT Assay involves the incubation of cultured mammalian cells in contact with a device and/or extracts to determine biological response.

Incucyte® Cytotox Dyes, in combination with the Incucyte® Live-Cell Analysis System, kinetically measure dynamic changes in cell membrane integrity to quantify cytotoxicity over multiple days. The Incucyte® Cytotoxicity Assay provides real-time measurements of cell death in response to treatments, pharmacological agents or environmental factors and can be used to determine biocompatibility.

While not CFR 21-compliant, the Incucyte® Live-Cell Analysis System is ideal for research and development studies across multiple drug delivery applications.

Microbial contamination can be present in raw materials or introduced during production. To prevent biofilms and corrosion, cooling water for autoclaves or instruments for production, like welders or drills, must be free from bacterial contamination. Testing along manufacturing as per ISO 11737-1 is crucial to ensure product quality and patient safety. A knowledge of bioburden (population of viable microorganisms) is essential to validate the sterility assurance level (SAL) and monitor cleaning processes and raw materials.

Combining these controls with continuous air monitoring is part of the Contamination Control Strategy described in GMP Annex 1. Continuous monitoring is a must to evaluate microbial flora at manufacturing facilities for deviations from the norm or to detect undesirable organisms.

Sartorius Microsart @Filter units for standard microbial enumeration protocols per USP <61> or MD8 Air Sampler enable efficient and accurate detection of potentially pathogenic or spoilage microorganisms:

- Save time with ready-to-use sterile filtration devices

- Minimize the risk of secondary contamination and false positives

- Retain smallest airborne micro-organisms with convenient eight-hour non-stop active air monitoring

Request More Information Explore Microbiological Testing Solutions

Read the blog post: Somethin' Buggin' Ya? Get the Basics of Bioburden Testing

Cleanliness determination or rinsing of the device after manufacturing process requires highly purified water (DI, RO, EDI Ultrapure), which is deionized and free from impurities, like bacteria or particles. It feeds lab equipment like washing machines, steam sterilizers or autoclaves or flushes the device before particulate matter analysis.

Medical devices in direct contact with the patient must be scrupulously clean and free of interfering residues. According to VDI 2083 and ISO 14644-9, cleanliness can be assessed by guiding the flushing medium through filter membranes possessing an appropriate porosity for the particle size to be determined. The filters containing the particles are then dried and analyzed either gravimetrically or microscopically.

Sartorius’ Cellulose Nitrate Membranes offer precise surface capture and reliable optical analysis. Rinse your device with Sartorius Arium®️ Water Purification Systems for impurity-free and safe operation and determine the total particle burden with Cubis®️ II balances :

- Membrane filters with excellent retention rates

- Ready-to-use ultrapure, particle-free rinsing water and optimal endotoxin removal by adding an Arium®️ CellPlus Ultrafilter

- Cubis®️ II Titanium weighing pans for uncompromised accuracy

Relying on a partner with a strong track record in key technologies (weighing, filtration, liquid handling, and water purification) will complement your in-house expertise, whether you are a medical device manufacturer, system integrator or engineering firm. We strive to help you to develop medical device solutions that meet the highest quality standards. Focus on your core business and let Sartorius serve you as a best-in-class supplier and one-stop solution provider.

- Ready-to-use filtration devices & membranes

- Error-proof process automation with WZA Integrated Weigh Cells and rLINE® Robotic Dispenser Module

- Aseptic connection & disconnection, with diverse fluid transfer systems to standalone components

- Customized filtration or liquid handling components to avoid user-based variance or to aseptically vent your device

- Ready-to use sets for Transfer - Transport – Storage of critical medical fluids

- Data Analytics Umetrics® Suite to optimize your manufacturing process with actionable insights

Related Blog Posts

Frequently Asked Questions

Prior to sterilization, bioburden testing is used to determine the total number of viable microorganisms on all or part of a medical device surface. This is one of the most-used microbiological tests in the Medical Device industry.

As required by industrial standards such as ISO 11737-1, microorganisms should be suspended in the proper liquid, captured using membrane filtration and grown on a culture medium. Thus, using the right products and procedures to determine bioburden is essential and helps reduce risks to patient safety.

Discover our solutions for Microbial Enumeration Microbiological Testing for Medical Devices

Design of Experiments (DOE) is a data analytics method that helps you plan, conduct, analyze and interpret controlled tests to determine which factors exert influence over your product quality, stability, or other key process attributes. Rather than experimenting with one parameter at a time, DOE speeds up the process and helps you identify important interactions by manipulating multiple factors at the same time.

Explore more QbD and DOE Software

The total solid content is defined as the mass of polymer per volume of latex, given in percent per weight (i.e. volume of particle phase to total volume of dispersion). A finished medical glove has a TSC of 100% since the substrate should not contain appreciable or significant amounts of water.

Moisture analyzers LMA200 can deliver TSC results within minutes. LMA200 helps optimize production of gloves and saves raw materials by applying the exact amount of latex your product needs.

Discover the LMA200PM Moisture Analyzer

Nanotechnology solutions are commonly combined with medical devices to help drugs reach their target. Tangential flow filtration (TFF) enables simple diafiltration, while maintaining a constant sample volume and can easily be placed under sonication to prevent aggregation.

Watch our bubble point video to learn how you can easily verify the filter integrity.

An ultra-microbalance with a scale interval of 0.1 μg and maximum weighing capacity offers a resolution in 21 million steps. In weight units, this is fine enough to measure a weight of 1 g of a total mass of 21 tons.

This high resolution provides ideal support for measuring the smallest sample weights below 1 mg within one part per thousand.

Read the White Paper: The Perfect Microbalance for Every Application

Professional training is a very good option to improve pipetting skills. Proper technique will increase the quality of results significantly, especially when working with viscous, volatile, or liquids with low surface tension. Ask your pipette provider if they offer training courses.

According to Annex 1, it is recommended for manufacturers to employ a diverse range of methods including contact plates, settle plates, and volumetric air sampling. It is crucial not to solely rely on a single method and instead utilize a combination of these techniques.

To ensure the microbiological safety of sterile medical devices, manufacturers undertake various measures. Sterility testing is conducted following established procedures outlined in pharmacopoeias, such as USP <71> and Eur. Ph. 2.6.1, as a release testing to verify the absence of viable microorganisms.

Medical device manufacturers are responsible for understanding the bioburden of the device and validating the sterilization process, aiming for a low Sterility Assurance Level (SAL) with a minimal probability (10-6) of surviving microbes. Each batch must demonstrate sterility, and sterility assurance throughout the product's shelf life is ensured. Compliance with standards like ISO 11137 is essential for sterilization process validation.

A product becomes an IVD when it is intended to be used for the examination of human specimens, including blood, urine, and tissue, in order to provide information for diagnostic, monitoring or compatibility purposes. IVD products can include reagents, instruments, and systems used to perform tests on samples for the detection, quantification, or measurement of specific analytes or biomarkers. The classification of a product as an IVD depends on its intended use and its compliance with applicable regulatory requirements.

Sartorius' precision infusion pump testing solutions offer medical device manufacturers a range of benefits that ensure compliance with industry standards such as AAMI TIR 101, IEC 60601-2-24, FDA, MDR, and GMP. By utilizing our Cubis® II balances, manufacturers can achieve high resolution in flow rate and accuracy testing, which is critical for patient safety and device reliability. Visit our page to learn more about how our pump testing solutions can enhance your medical devices' performance and reliability.